Clothing

Get Your Custom Look

Create your personalized look for any event or occasion. We offer various products for all your printing and apparel design needs. Custom shirts make great personalized gifts for family and friends!

From corporate dress wear to your firms next clothing code we have you covered. We provide a preview of how your logo will look on the color and clothing of your choice. We cover everything from stag and doe to big concerts.

We provide discounts for teams and local businesses looking to order 10+ items.

Printing Options

Find the best option for your apparel project

Screen Printing

Screen printing is a technique for decorating clothing by pushing ink through a mesh stencil to create a design. For each color in the design, a separate screen stencil is created, and a squeegee is used to force ink through the open areas of the mesh onto the fabric. This method is known for creating durable, vibrant prints that have a thick, tactile feel.

How it works:

- Stencil creation: A design is first created and then transferred onto a screen made of a fine mesh. Areas of the screen that are not part of the design are blocked out with a resistant material.

- Ink application: For each color, a separate screen is prepared. Ink is spread over the screen, and a squeegee is used to force the ink through the mesh onto the garment below.

- Color layering: Each color is applied one layer at a time, so a multi-colored design requires multiple screens and print passes.

- Result: After the ink is applied and the garment is dried, the result is a bold, long-lasting print. The ink sits on top of the fabric, which gives it a distinct feel.

Key features:

- Durability: Screen printing is a very durable method, and the prints can withstand wear and tear.

- Vibrancy: The process produces vibrant, high-quality colors with precision.

- Versatility: It can be used on a wide range of fabric types and materials.

- Cost-effectiveness for bulk orders: While the setup for each color can be time-consuming, the actual printing process is fast, making it cost-effective for large orders.

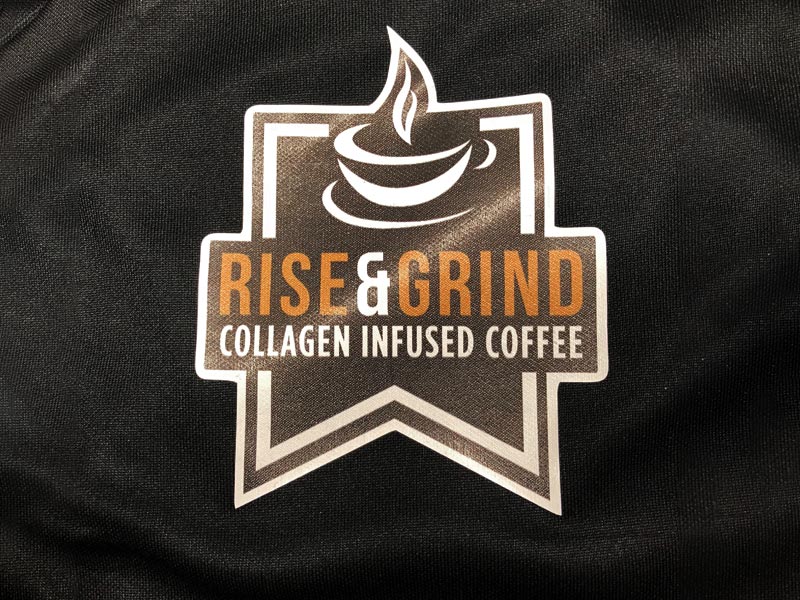

Heat-Transfer-Vinyl (HTV)

Heat transfer vinyl is a type of material used to decorate clothing by applying pre-cut or printed designs onto fabric using heat and pressure. HTV consists of a colored vinyl film with a heat-activated adhesive, laminated onto a clear carrier sheet that holds the design in place until it is pressed onto the item. This method creates a permanent and durable decoration, commonly seen on sportswear, t-shirts, and other soft goods like bags and hats.

How it works:

- Design creation: A design is created with HTV, either by cutting solid colors from a sheet of vinyl or by printing a design onto special printable HTV.

- Weeding: The excess vinyl that is not part of the design is manually removed, a process called “weeding”.

- Placement: The design, which is held together by the carrier sheet, is positioned on the clothing item.

- Application: Heat and pressure are applied using a heat press or a household iron, which melts the adhesive and permanently bonds the vinyl to the fabric.

- Finishing: Once the design has cooled, the clear carrier sheet is peeled away.

Key features:

- Versatility: HTV comes in a wide variety of colors and finishes, including glitter, metallic, holographic, and glow-in-the-dark options.

- Durability: The application creates a permanent bond that can withstand washing, though it may eventually peel or crack with extensive use.

- Ease of use: The process can be done with a cutting machine and a heat press for professional results or a household iron for a DIY approach.

- Specific types: There are various types of HTV for different projects, such as stretch vinyl for athletic wear or CPSIA-Certified vinyl for children’s clothing, which ensures it’s free of harmful chemicals.

Embroidery

Embroidery is the art of decorating clothing and other fabrics by stitching designs, logos, or patterns directly into the material with needle and thread. This method creates a textured, raised, and durable design that can be done by hand or with a computerized embroidery machine. It is a timeless and professional technique often used for branded apparel like business shirts and uniforms, but can also be applied for artistic or personalized purposes.

How it works:

- Machine embroidery: A design is created digitally, loaded into an embroidery machine, and then the machine automatically stitches the design onto the fabric.

- Hand embroidery: Uses a needle and thread to create designs through a variety of stitches, such as the cross stitch, running stitch, and satin stitch.

Key features:

- Durability: The stitches are resilient and the design is robust and less prone to fading or damage over time, even with frequent washing.

- Professional look: Embroidery provides a dimensional, tactile, and prestigious appearance, making it a popular choice for professional attire and logos.

- Texture: The use of thread creates a raised texture that adds a unique, artistic, and sophisticated finish to the garment.

Direct-To-Garment (DTG)

Direct to garment is a digital printing process that applies a design directly onto fabric using specialized inkjet printers, similar to how a document is printed on paper. This method uses water-based inks that are absorbed into the fibers after the garment is pre-treated and cured, resulting in a soft, smooth finish with high-quality, full-color graphics, making it ideal for detailed designs and small print runs

How it works:

- Pre-treatment: The garment is treated with a bonding agent to help the ink adhere to the fibers.

- Printing: The item is placed in the DTG printer, and the design is printed directly onto the fabric, much like a standard inkjet printer.

- Curing: The printed garment is then heat-pressed to cure the ink, locking it into the fibers and making the design durable.

Key features:

- High-quality images: Can reproduce intricate details, gradients, and photographs with vibrant colors.

- Soft feel: The ink soaks into the fabric, creating a soft, flat print that doesn’t crack or peel easily.

- Ideal for small orders: Efficient for one-off prints, custom items, and short runs.

- No minimums: Allows for the creation of custom apparel with no minimum order requirements.

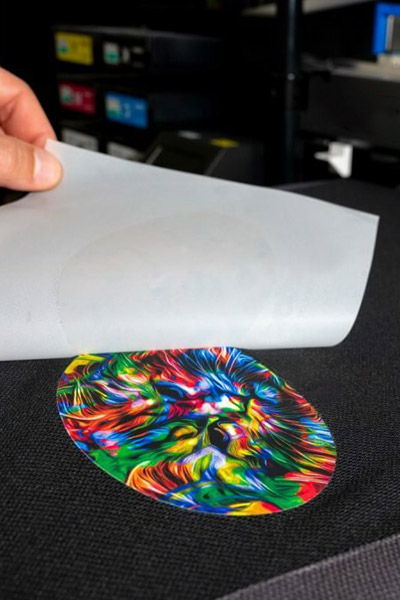

Direct-To-Film (DTF)

Direct-to-film uses a printing process where a design is first printed onto a special film and then transferred to the fabric using a heat press. This method creates durable, high-quality prints with vibrant colors and intricate details on a wide range of fabrics like cotton, polyester, and blends.

How it works:

- Print on film: An inkjet printer applies a design in water-based inks onto a special transfer film.

- Apply adhesive: A powdered adhesive is applied to the wet ink on the film, acting as a bonding agent.

- Heat cure: The film and powder are cured with heat to bond the design and prepare it for transfer.

- Transfer: The cured design is placed on the garment and bonded with a heat press.

- Peel film: After cooling, the film is peeled off, leaving the finished design adhered to the fabric.

Key features:

- Versatility: It works on a broad range of materials, including cotton, polyester, nylon, and blends, and can be used for both light and dark fabrics.

- Quality: DTF produces vibrant, detailed, and opaque prints, even with complex designs and on darker garments.

- Durability: The prints are long-lasting and resistant to washing and wear.